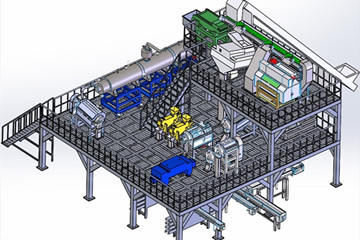

巴氏奶加工生產(chǎn)線

Pasteurized milk processing line

巴氏奶是利用鮮牛奶作原料����,利用巴氏消毒法��,即72-75°C下加熱10-15秒的低溫殺菌�����,在殺滅牛奶中有害菌群的同時(shí)完好地保存了營(yíng)養(yǎng)物質(zhì)和純正口感�。經(jīng)過(guò)離心凈乳����、標(biāo)準(zhǔn)化、均質(zhì)����、殺菌和冷卻,以液體狀態(tài)灌狀�,直接供給消費(fèi)者飲用。

Pasteurized milk uses fresh milk as raw material and pasteurized by pasteurization, that is, heating at 72-75 ° C for 10-15 seconds. Pasteurized milk can kill harmful bacteria in milk and preserve nutrients and pure taste. After centrifugation, standardization, homogenization, sterilization and cooling, it is poured into liquid state and directly supplied to consumers for drinking.

巴氏奶的三種包裝:屋頂包�����,也叫新鮮屋���,巴氏塑料袋和玻璃瓶裝�����。

Three kinds of packaging of pasteurized milk:Roof bags, also known as fresh houses, pasteurized plastic bags and glass bottles.

產(chǎn)量范圍:2TD-500TD

Production range: 2td-500td